Machinery and tools

These facilities are used for mechanical processing: over 4000 sqm of lab and offices (800 sqm used for assembly department).

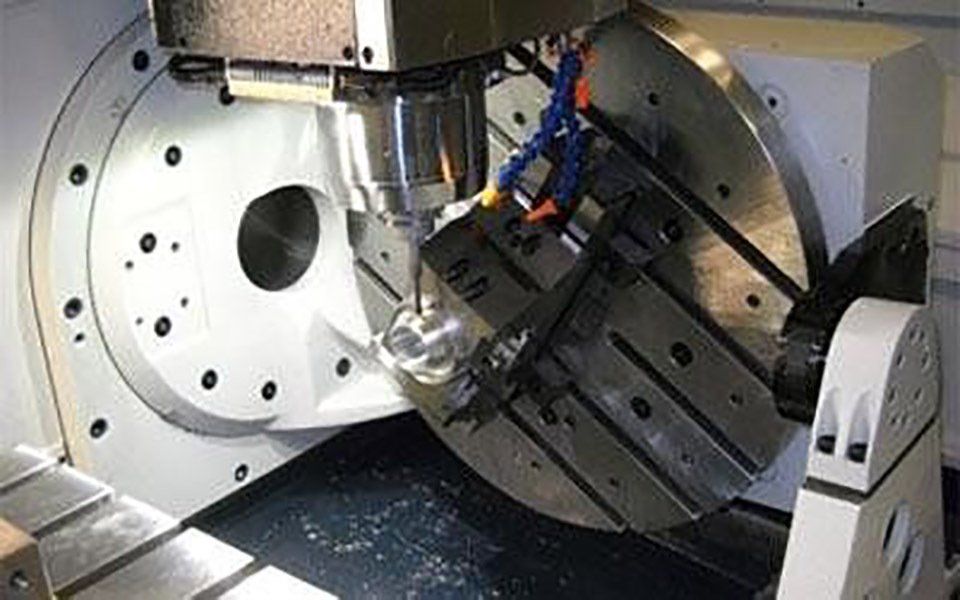

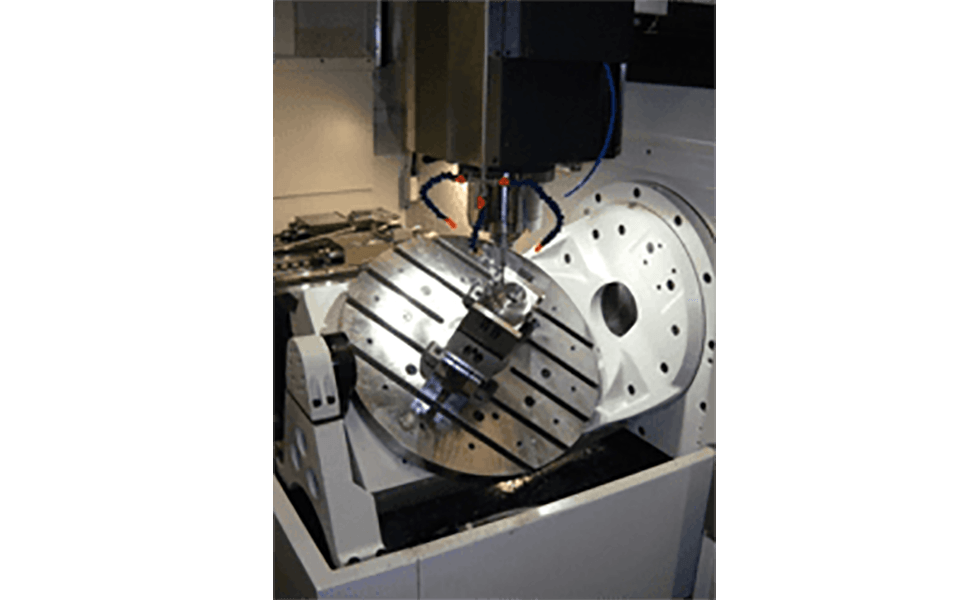

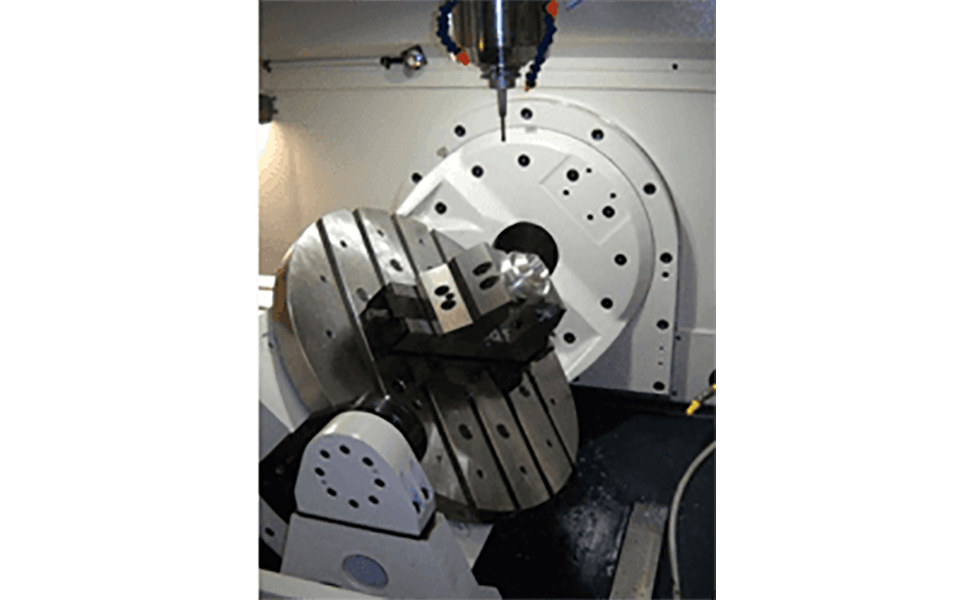

NUMERICAL CONTROL MACHINES

1 x FPT DINOX 350, 5-axis continuous vertical milling machine, high precision and dynamic for high-speed machining (X 3500 - Y 2500 - Z 1300) (C-axis rotation +/- 270 ° - A-axis rotation +/- 185 °). Machinery featuring 4.0 technology.

1 x MAZAK INTEGREX I 200S 5-axis continuous turning centre - multitasking horizontal milling with COUNTER SPINDLE - 36-tool magazine.

2 x Mazak Variaxis J-600 / 5X milling machine - Multi-plane Machining Centre with 5 simultaneous axes (X 850,

Y 550, Z 510) (Table rotation, C, 0.0001 °, 360 ° - Table tilt, B, - 120°+90 °). Machinery featuring 4.0 technology.

1 x MAZAK VTC800-30SR 5-AXIS milling machine (X 3000, Y 800) 48 tools with continuous tilting head +/- 110 degrees - equipped with continuous rotary table d.500 - can be assembled horizontally or vertically.

1 x MAZAK VTC800-20 SR 5-AXIS milling machine (X2000, Y800) 48 tools with continuous tilting head +/- 110 degrees equipped with continuous rotating table d.500 - can be assembled horizontally or vertically.

1 x HEDELIUS BC 100 40-tool milling machine (X3500 - Y1000 - Z700) equipped with 4th + 5th axis continuous divider.

1 x SPINNER Milling Machine U 5 1520 -5 axis 48 TOOLS with integrated rotary table 4th and 5th continuously tilting rotary axis and combined cross table (X1520, Y520, Z460).

1 x horizontal turning /milling centre “MULTITASKING” YAMAZAKI MAZAK model Integrex i200S - Matrix 2 (C-axis continuously on the 2nd spindle - storage for 36 chain tools with CAPTO attachment).

1 x AWEA BM1200-5-axis CNC Milling Machine FANUC 24 TOOLS with continuous tilting divider COMMAND.X1250 Y600 Z600.

1 x SIGMA MISSION 3 CNC Machining Centre- (FANUC) 21 tools ISO 40 with 4 axes. Scotti divider. (X1000 - Y600 - Z600).

1 x SIGMA MISSION 5 CNC Machining Centre- (FANUC) 21 tools ISO 40 with 4 axes. Scotti divider. (X1250 - Y600 - Z600).

1 x FANUC ROBODRILL ALPHA CNC Machining CentreT21 B - 21 tools (X700 - Y400 - Z350).

2 x HAAS Super Mini Mill CNC 10 tools (x400 y300 z250).

1 x Doosan Puma 5100LYA, 4-axis CNC lathe with motorised tools (max turning d. 550mm - max turning length between centres 2050mm - max d. from bar 116.5 mm - max d. rotating on the bed 880 mm - max d. rotating on the carriage 817 mm). Machinery featuring 4.0 technology.

1 x Doosan Puma 2600Y-II, 4-axis CNC lathe with motorised tools (max turning diameter 376 mm - max turning length between centres 760 mm - max diameter from bar 81 mm - max rotating diameter on the bench 780 mm - max diameter rotating on the carriage 680 mm). Machinery featuring 4.0 technology.

2 x BIGLIA B1200 FANUC 18 TiB lathe with 12 motorised tools. C-axis and YD-axis max turning 500 - length max turning 1200.

2 x BIGLIA B650 FANUC 18 TiB lathe with 12 motorised tools. C-axis and YD -axis max turning 500 - length max turning 650.

1 x Lathe YAMAZAKI MAZAK mod. Q250M * 1000L with Smooth C CNC (12 driven tools, max 360 - length mx turning 1025).

1 x BIGLIA B501 CNC FANUC lathe complete with "LNS HYDROBAR" bar feeder up to d. 68. Automatic. d. 250.

1 x PADOVANI Lathe Mod. 165 CNC FANUC. Automatic. d. 250.

1 x DAEWOO PUMA 350 B CNC FANUC 18 TC lathe. Automatic. d. 381 spindle ASA11 useful bar passage d. 116 max turning diameter 550x1000 mm.

1 x ACCUTEX AU300 WIRED NUMERICAL CONTROL EDM with tilting head +/- 30 ° and working range X350, Y250, Z300.

1 x FANUC ALPHA - NUMERICALLY CONTROLLED WIRE EDM – 1 with tilting head +/- 30 ° and working range X600, Y400, Z310.

CAD / CAM programming technical office with 3D solid model MASTERCAM.

Traditional machines and tools

1 x FREEPORT Tangential Grinding Machine X1016 - Y508.

1 x FREEPORT 700x300 Tangential Grinding Machine with

automatic cycle.

1 x Universal Grinding Machine PARAGON Mod.GU

32X100P DISPLAYED n.

1 x Universal Grinding Machine MORARA mod EA100

with CN MARPOSS mod. E44.

1 x PPL 270x1500 parallel lathe shown.

1 x Parallel lathe PBR 200x1500 shown.

1 x OMG ZANOLETTI 260x1500 parallel lathe shown.

1 x MISAL 745 / U Milling Machine shown.

1 x RAMBAUDI MS / 3P Milling Machine shown.

1 x RAMBAUDI NUOVA MS3 / P Milling Machine shown.

1 x RAG TCS 40 drill with cross table and automatic descent

1 x RAG 25 pillar drill.

1 x IM type IMM 135 ATM tapping drill complete with precision cross table.

1 x IM Tapping Machine type IMM 118 / TM.

2 x "WHITE" handheld bandsaw d. 220.

2 x MEP CNC bandsaw d. 260 bar feed.

1 x MEP semi-automatic bandsaw d. 230.

1 x 300 AMP wire welder.

1 x Hydraulic press 50 T.

1 x Hydraulic press 25 T.

2 x boards to divide.

1 x divider.

1 x PERINI CMP 250 slat.

2 x Micro shot-peening Machine with glass microspheres.

1 x ROLLWASH tumbler.

1 x Torrent 500 parts washer.

3 x Parts washers: TRADITIONAL, ULTRASOUND, STEAM.

1 x LASER Marking Machine - SISMA.

2 x Micro dot Marking Machine with PLC.

1 x Somaut stop Marking Machine.

1 x 0 Flag hoists with up to 20 quintals capacity

4 x MONTEFIORI overhead crane - 50 quintals

3 x Forklift NISSAN / TOYOTA - 20 quintals and 25 quintals capacity

2 x FORD TRANSIT CH350 curtain side truck - 16 quintals capacity

1 x Truck with IVECO rib - 35 quintals capacity

1 x MERCEDES truck - 55 quintals capacity

Internal testing point

Our company also has an internal testing space with:

1 Air-conditioned metrology lab complete with a 3D measuring machine (CMM) Brand DEA mod. GLOB PERFORMANCE SILVER measures 09-20-08 X900 Y2000 Z800 - TESASTAR Indexable head - TESASTAR SM80 - measuring head LEITZ LSP - Software X1H PCDIMIS CAD ++

2 POLI 3D Measuring Machine Mod. SKY3 650x500x500.

1 TRIMOS VERTICAL V4 700 altimeter with macro accessory kit.

5 TRIMOS TVA700 VERTICAL 3 electronic altimeters with accessories.

2 Preset mode ELBO E 340 with projector.

1 GALILEO electric hardness tester for HRC, HB measurements.

1 Durometer for HRC measurements.

1 Mitutoyo CV-3200 profilometer.

1 Mitutoyo PH-A14 profile projector.

1 Electric reset for holes and micrometers TAR-AL500.

2 Mitutoyo portable roughness tester.

1 portable hardness tester for HB measurements.

Traditional equipment for mechanical dimensional and geometric inspections (see attachment).

Data processing centre for accounting, storage and production management which consists of: presence and production control systems in the workshop so that the production progress can be monitored and checked directly in real time.